Hydraulics Fittings, Quick Release Couplings, JIC Fittings, Flareless Fittings

Introduction

FAV range of Hydraulics Fittings provides secure, tough, and reliable tube connection that with exceptional leak-tight quality. FAV Hydraulic Fittings are available in Stainless Steel, Brass, Steel and Monel.

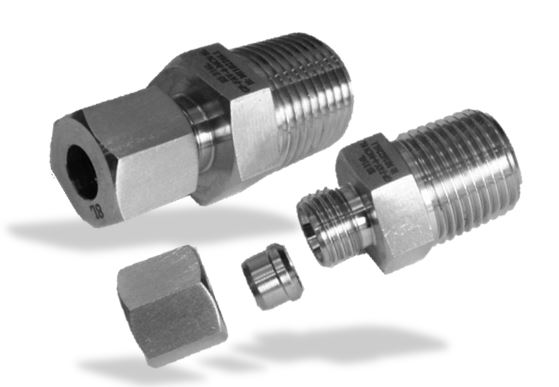

Hydraulics fittings consist of a body, a one-piece ferrule, and a nut are available in carbon steel, brass, and stainless steel. With a large number of configurations, there will be a fitting that is ideally suited to meet the requirements of almost any industrial application. On assembly, the ferrule “bites” into the outer surface of the tube with sufficient strength to hold the tube against pressure and seal the fluid, without considerable distortion of the inside tube diameter. Hydraulics fittings have a visible bite, allowing the fitting assembler to visually inspect the bite quality, thus significantly minimizing the risk of improper assembly and related service problems. Hydraulic fittings are especially suitable for use with tube wall thickness ranging from medium to extra heavy. For proper bite, bottoming out the tube is essential for the make-up of the fitting. Leak-free performance is guaranteed when bite type fittings are assembled properly. No special tools are required to obtain proper installation.

Applications

For use with applications such as: Construction machinery, Textile machinery, Machine tools, Chemical, Marine, Military, and most other high pressure hydraulic applications. Applications using thick wall tubing where flaring is not practical.7000 Flareless Fittings are NOT RECOMMENDED for use in instrumentation applications where toxic and noxious gases are present. A bite type fitting is sometimes incorrectly referred to as a compression fitting. Compression fittings are designed for use with soft tubing and are not interchangeable with bite type fittings

Bore type quick release couplings have no check valves. These are ideal for maximum flow application. Their smooth, open bore offers the bottom pressure drop of any quick disconnected couplings and allows them to be through cleaned. Since there is no valves, fluid flow should be shut off before the coupling is disconnected.

Quick Release Couplings

Quick Release Couplings type coupling work on Push and Pull principle. When the Adaptor is pushed to the coupler, it is accurately held by the self-locking arrangement resulting in a positive & leak proof connection. This action simultaneously opens the valve & fluid flow starts. To disconnect, pull back the sleeve of the coupler, the Adaptor ejects out and the valves shut off automatically. Valves are provided in type one way sealing & two way sealing

JIC Fittings

JIC Fittings comprises of three precision machined components like Body, Sleeve and Nut. Main construction consists of three pieces: the body, sleeve & nut. The tube end is flared to 74 degrees included angle and held in between the main body nose and the sleeve nut which is on top of them, thus resulting in a very effective leak-proof joint, full flow connection in process tubing. Flare fitting design allows for repeated disassembly and re-assembly with no need to replace any components. A wide range of configurations are available such as straight connectors, elbows, union, tees, and crosses as well as unique special adapters. Standard flare fitting materials include brass, carbon steel, and stainless steel.

JIC fittings are engineered to save the user money and time. They are economically priced and provide excellent service as well as longevity. Providing exceptional results and quality service, these 37°flare fittings are favoured by many industries and consistently exceed the user’s expectations